dinglimachine01@gmail.com

+86 16638159081(Wechat/WhatsApp)

dinglimachine01@gmail.com

+86 16638159081(Wechat/WhatsApp)

We are pleased to announce that Zhengzhou Dingli New Energy Equipment Co., Ltd. has established a technology partnership with puro.earth, the world's leading engineered carbon removal credit platform. The partnership means that recyclers will be able to

2025-11-11>>

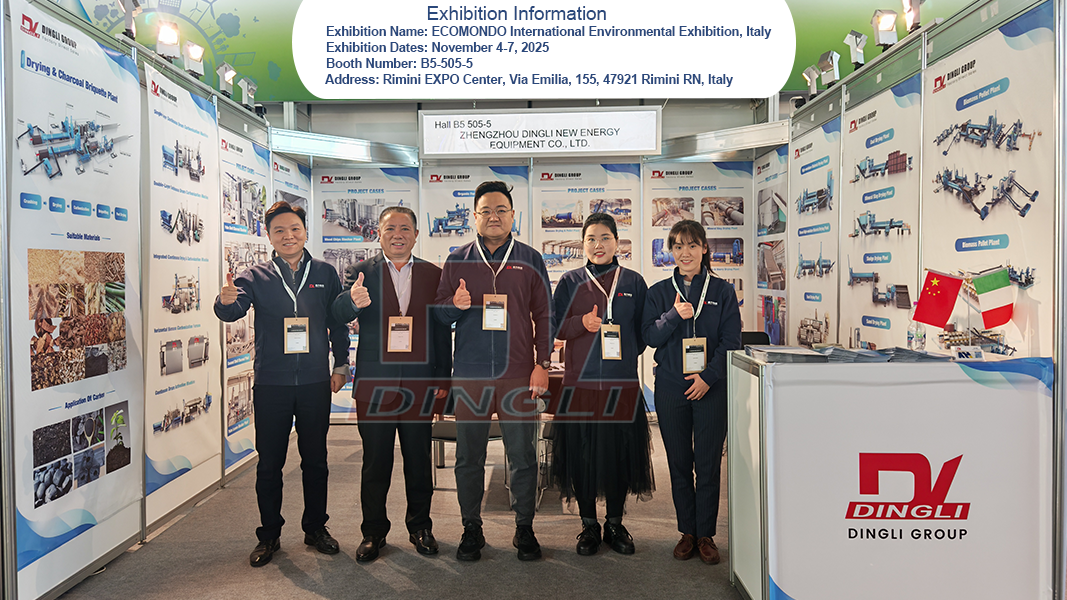

Exhibition Name: ECOMONDO International Environmental Exhibition, Italy Exhibition Dates: November 4-7, 2025 Booth Number: B5-505-5 Address: Rimini EXPO Center, Via Emilia, 155, 47921 Rimini RN, Italy

2025-11-03>>

From July 8th to 13th, 2025, the highly anticipated Entrepreneurs' Business Cooperation Trip to Russia successfully concluded. Mr. Li Liuji, founder of Zhengzhou Dingli Group, was invited to participate in this trip, joining many outstanding entrepreneur

2025-07-13>>

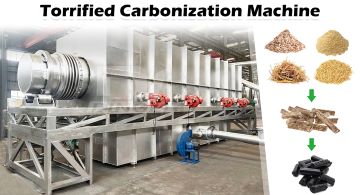

In the field of biomass processing and energy conversion, the stability and economic efficiency of equipment often determine the success or failure of a project. Continuous carbonization equipment is becoming the preferred choice for an increasing number

2026-02-12>>

With unprecedented global attention focused on climate change and resource crises, continuous carbonization technology has rapidly evolved from a cutting-edge processing method into a cornerstone technology supporting the circular economy and the "dual-c

2026-02-05>>

Continuous carbonization equipment is a highly efficient system integrating carbonization and pyrolysis processes, widely used in biochar, carbon-based fertilizers, and environmental energy fields. Through precise control of carbonization temperature and

2026-02-04>>

Continuous carbonization equipment demonstrates a series of unique advantages in the biomass carbonization process. Firstly, the equipment adopts a continuous production mode, avoiding the production fluctuations and inefficiencies of traditional batch-ty

2026-02-02>>

From January 26th to 28th, 2026, Dingli Group successfully participated in IFAT Saudi Arabia 2026, held at the RFECC Exhibition Center in Saudi Arabia. As a major professional exhibition in the environmental protection and resource recycling field in the

2026-01-30>>

With the global shift in energy structures and increasing concern for environmental protection, biomass energy has emerged as a sustainable development solution. Continuous carbonization equipment utilizes advanced high-temperature pyrolysis technology to

2026-01-29>>

Continuous biomass carbonization equipment integrates mechanical transmission, thermal control, and automation technologies, representing a key direction in the development of carbonization equipment. Its core principle lies in achieving uniform biomass c

2026-01-27>>

In the context of increasingly stringent environmental regulations, the energy consumption and emission control of carbonization equipment have become a key focus for customers. Continuous carbonization machines, through optimized furnace structure and he

2026-01-23>>

The widespread market acceptance of continuous carbonization machines stems from their mature technical structure and stable operating performance. The equipment adopts a modular design concept, with a compact core carbonization section and high thermal e

2026-01-21>>

The newly commissioned EFB Pellet Carbonization Project in Malaysia has achieved a stable output of 2 tons per hour. The project focuses on the deep processing of EFB pellets, turning palm residues into premium biomass charcoal products.

2026-01-15>>

Driven by the "dual carbon" goals and the concept of a circular economy, continuous EFB carbonization equipment is gradually becoming an important component of the transformation and upgrading of palm oil companies.

2026-01-13>>

With the continuous growth of global coffee consumption, the amount of coffee grounds produced is also constantly increasing. If large quantities of coffee grounds are simply discarded, they not only occupy storage space but also easily generate odors and

2026-01-09>>

With the continuous expansion of the biochar market, relying solely on raw material sales is no longer sufficient to meet companies' profitability needs. Transforming low-value raw materials into high-value products through biomass carbonization equipmen

2026-01-08>>

Against the backdrop of a global push for a low-carbon economy, the biomass energy industry is experiencing significant development opportunities. Corn cobs, as a common agricultural byproduct, have the advantages of being widely available, low-cost, and

2026-01-06>>

On December 27, 2025, Dingli Group's 25th-anniversary celebration was grandly held in Zhengzhou. Partners from across the country, industry guests, and the Dingli Group management team gathered together to witness the company's glorious journey of 25 ye

2025-12-29>>

Amidst the trend of energy conservation, emission reduction, and low-carbon development, more and more companies are paying attention to the issue of waste treatment in their production processes. Sawdust carbonization machines are an important tool to he

2025-12-24>>

Biomass energy, as a renewable and green energy source, is receiving increasing attention in the global energy market. In this wave of green energy, wood chip carbonization machines, as important equipment for converting wood chips into high-efficiency ca

2025-12-23>>

In the process of global energy structure transformation, the importance of renewable energy is becoming increasingly prominent. Rice straw carbonization machines, as part of biomass energy, provide strong support for the development of green energy. They

2025-12-20>>

In recent years, coconut shell carbonization machines have gradually shown promising application prospects in various industries. With the continuous development of the coconut processing industry, the production of coconut shells is constantly increasing

2025-12-19>>

Amidst the continuous development of renewable energy, biomass energy is gradually becoming an important alternative to traditional energy sources. The sawdust carbonization machine processes sawdust, converting it into a more stable and efficient biomass

2025-12-18>>

We are honored to announce that our company has been invited to participate in IFAT Saudi Arabia 2026 and cordially invite you to visit our booth!

2025-12-15>>

Biomass resources, as an important component of renewable energy, are gradually replacing traditional energy sources and becoming a new support for low-carbon development. Biomass pyrolysis carbonization machines play a crucial role in this process, trans

2025-12-12>>

Biomass resources, due to their renewable and environmentally friendly characteristics, are becoming a new growth point in the energy industry. The application of biomass pellet torrefaction and carbonization machines upgrades biomass pellets from ordinar

2025-12-11>>

Against the backdrop of deepening "dual carbon goals" and sustainable development concepts, biomass carbonization technology is receiving increasing attention. Nut shell carbonization machines, as a key piece of equipment in this field, provide a brand-

2025-12-09>>

In the palm oil cultivation and processing industry, a large amount of EFB (empty fruit bunches) is generated annually as a byproduct. In the past, this waste was difficult to transport, lacked effective applications, and even became an environmental burd

2025-12-05>>