dinglimachine01@gmail.com

+86 16638159081(Wechat/WhatsApp)

dinglimachine01@gmail.com

+86 16638159081(Wechat/WhatsApp)

Semi-continuous carbonization machine is a biomass pyrolysis and carbonization device where the carbonization process is partly continuous and partly intermittent. Specifically, the feeding and charcoal discharge processes are carried out in batches and intermittently, but the equipment outside of these two stages operates continuously and uninterruptedly, controlled by an electrical control system.

It is easy to operate, safe, and environmentally friendly, with high production efficiency, and can save a lot of energy.It is ideal equipment for long-rod biomass carbonization. Combined mode of multiple units, carbonized combustible gas is used in series, saving fuel in carbonization production and improving enterprise efficiency.

| Model | Capacity(m³) Carbonization time |

Length(m) | Width(m) | Internal Length(m) | Internal Diameter(m) | Material |

|---|---|---|---|---|---|---|

| DLWT1600 | 7.08/9h | 2.9 | 2.2 | 1.9 | 2.5 | Carbon steel |

| DLWT2000 | 9.92/10h | 3.9 | 2.2 | 1.9 | 3.5 | |

| DLWT3100 | 15.30/12h | 5.9 | 2.2 | 1.9 | 5.4 |

1. Protect the environment, make full use of crop residues, and turn waste into treasure.

2. Reasonable structure, stable working performance, easy operation.

3. Low water content, high density and incineration resistance.

4. Regular shape, reasonable layout, easy to use: uniform length and size, hollow or solid structure, conducive to combustion and use.

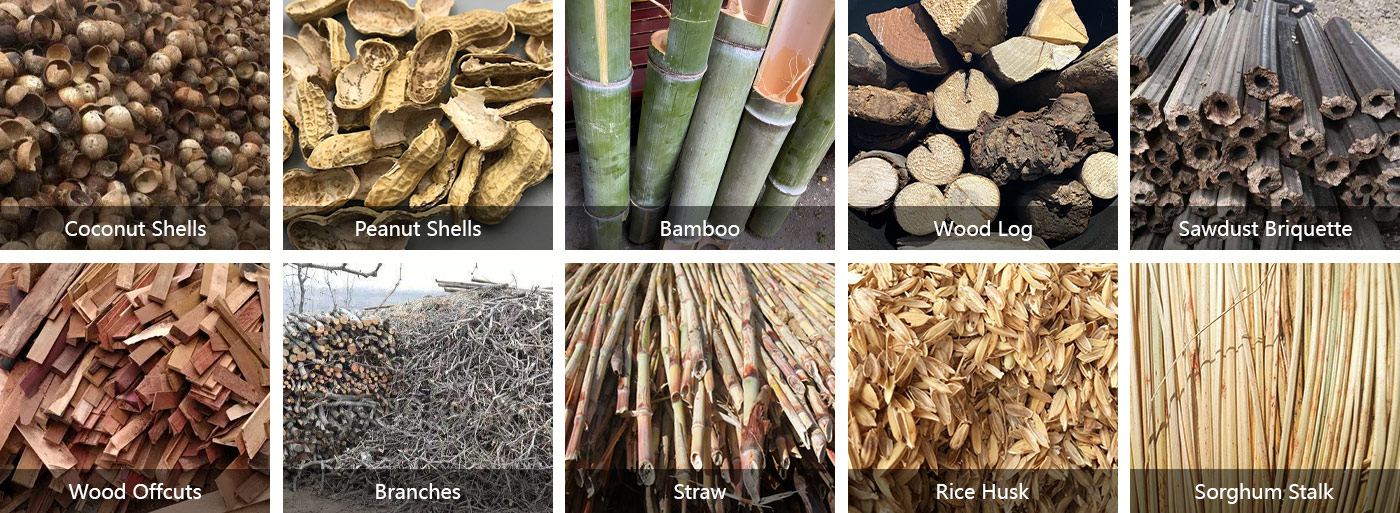

5. The equipment has wide adaptability, can be used to make toner from various raw materials, and press toner rods and toner balls of different shapes according to requirements.

Professional R & D design team, 300+ patent certificates.

The technical team customizes project solutions for customers.

Provide equipment installation and commissioning services.

The professional after-sales team is always at your service.